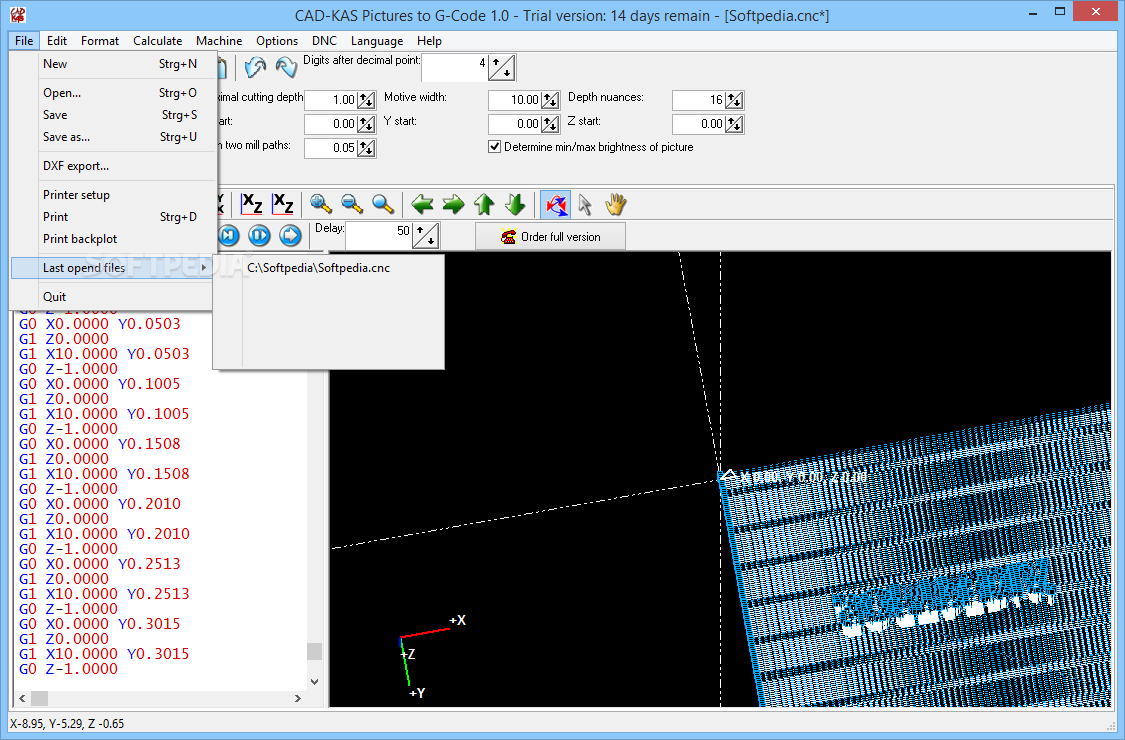

Mach3 is a software package which runs on a PC and turns it into a very powerful and economical Machine Controller. Mach3 is a full featured CNC controller suitable for controlling the Lathe,Mill, Plasma Cutter, Router, Engravers etc. Below is a list of Mach3 Mill G code with description. With ThumbnailCNC installed, all G-code files on your computer will be represented by a thumbnail (small picture) when browsing directories with Windows Explorer. features TextMilling - Engraving software for text milling with G-codes in CNC machines features. Step 3: Load the generated G-Code into your CNC milling software Open the G-code with your CNC milling machine software (e.g. Mach3) A blog on projects with robotics, computer vision, 3D printing, microcontrollers, car diagnostics, localization & mapping, digital filters, LiDAR and more.

- Milling G Code Software Windows 10

- G Code Milling Software

- Milling G Code Software Online

- G-code Text Engraving Milling Software

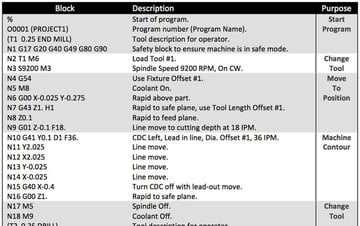

Complete g code list with m-codes for milling in the Fanuc, LinuxCNC, GRBL, and Haas dialects. We give a quick definition for all g code commands along with a link to tutorials and examples of how to use it. Click the g-code link (if any) to visit a tutorial from our popuplar online, free G-Code Training that shows examples and teaches how to program CNC machines using the g-code.

G Codes

Function | Notes | ||

| G00 | Move in a straight line at rapids speed. | XYZ of endpoint | |

| G01 | Motion | Move in a straight line at last speed commanded by a (F)eedrate | XYZ of endpoint |

| G02 | Clockwise circular arc at (F)eedrate | XYZ of endpoint IJK relative to center R for radius | |

| G03 | Motion | Counter-clockwise circular arc at (F)eedrate | XYZ of endpoint IJK relative to center R for radius |

| G04 | Dwell: Stop for a specified time. | P for milliseconds X for seconds | |

| G05 | Motion | FADAL Non-Modal Rapids | |

| G09 | Exact stop check | ||

| G10 | Compensation | Programmable parameter input | |

| G15 | Turn Polar Coordinates OFF, return to Cartesian Coordinates | ||

| G16 | Coordinate | Turn Polar Coordinates ON | |

| G17 | Select X-Y plane | ||

| G18 | Coordinate | Select X-Z plane | |

| G19 | Select Y-Z plane | ||

| G20 | Coordinate | Program coordinates are inches | |

| G21 | Program coordinates are mm | ||

| G27 | Motion | Reference point return check | |

| G28 | Return to home position | ||

| G29 | Motion | Return from the reference position | |

| G30 | Return to the 2nd, 3rd, and 4th reference point | ||

| G32 | Canned | Constant lead threading (like G01 synchronized with spindle) | |

| G40 | Tool cutter compensation off (radius comp.) | ||

| G41 | Compensation | Tool cutter compensation left (radius comp.) | |

| G42 | Tool cutter compensation right (radius comp.) | ||

| G43 | Compensation | Apply tool length compensation (plus) | |

| G44 | Apply tool length compensation (minus) | ||

| G49 | Compensation | Tool length compensation cancel | |

| G50 | Reset all scale factors to 1.0 | ||

| G51 | Compensation | Turn on scale factors | |

| G52 | Local workshift for all coordinate systems: add XYZ offsets | ||

| G53 | Machine coordinate system (cancel work offsets) | ||

| G54 | Work coordinate system (1st Workpiece) | ||

| G55 | Work coordinate system (2nd Workpiece) | ||

| G56 | Work coordinate system (3rd Workpiece) | ||

| G57 | Work coordinate system (4th Workpiece) | ||

| G58 | Work coordinate system (5th Workpiece) | ||

| G59 | Work coordinate system (6th Workpiece) | ||

| G61 | Other | Exact stop check mode | |

| G62 | Automatic corner override | ||

| G63 | Other | Tapping mode | |

| G64 | Best speed path | ||

| G65 | Other | Custom macro simple call | |

| G68 | Coordinate System Rotation | ||

| G69 | Coordinate | Cancel Coordinate System Rotation | |

| G73 | High speed drilling cycle (small retract) | ||

| G74 | Canned | Left hand tapping cycle | |

| G76 | Fine boring cyle | ||

| G80 | Canned | Cancel canned cycle | |

| G81 | Simple drilling cycle | ||

| G82 | Canned | Drilling cycle with dwell (counterboring) | |

| G83 | Peck drilling cycle (full retract) | ||

| G84 | Canned | Tapping cycle | |

| G85 | Boring canned cycle, no dwell, feed out | ||

| G86 | Canned | Boring canned cycle, spindle stop, rapid out | |

| G87 | Back boring canned cycle | ||

| G88 | Canned | Boring canned cycle, spindle stop, manual out | |

| G89 | Boring canned cycle, dwell, feed out | ||

| G90 | Absolute programming of XYZ (type B and C systems) | ||

| G90.1 | Absolute programming IJK (type B and C systems) | ||

| G91 | Incremental programming of XYZ (type B and C systems) | ||

| G91.1 | Incremental programming IJK (type B and C systems) | ||

| G92 | Offset coordinate system and save parameters | ||

| G92 (alternate) | Motion | Clamp of maximum spindle speed | S |

| G92.1 | Cancel offset and zero parameters | ||

| G92.2 | Cancel offset and retain parameters | ||

| G92.3 | Offset coordinate system with saved parameters | ||

| G94 | Motion | Units per minute feed mode. Units in inches or mm. | |

| G95 | Units per revolution feed mode. Units in inches or mm. | ||

| G96 | Motion | Constant surface speed | |

| G97 | Cancel constant surface speed | ||

| G98 | Canned | Return to initial Z plane after canned cycle | |

| G99 | Return to initial R plane after canned cycle |

Get a Powerful G-Code Simulator and Editor to Simplify G-Code Work

Function | Notes | |

| M00 | Program Stop (non-optional) | |

| M01 | M-Code | Optional Stop: Operator Selected to Enable |

| M02 | End of Program | |

| M03 | M-Code | Spindle ON (CW Rotation) |

| M04 | Spindle ON (CCW Rotation) | |

| M05 | M-Code | Spindle Stop |

| M06 | Tool Change | |

| M07 | M-Code | Mist Coolant ON |

| M08 | Flood Coolant ON | |

| M09 | M-Code | Coolant OFF |

| M17 | FADAL subroutine return | |

| M29 | M-Code | Rigid Tapping Mode on Fanuc Controls |

| M30 | End of Program, Rewind and Reset Modes | |

| M97 | M-Code | Haas-Style Subprogram Call |

| M98 | Subprogram Call | |

| M99 | M-Code | Return from Subprogram |

Bonus: Check Out our Other CNC Cookbooks for More In-Depth CNC Information!

If you’re a CNC Beginnner, check out our CNC Beginner’s Cookbook. It’ll get you up to speed with a solid CNC foundation fast.

We also have Cookbooks for Feeds and Speeds, G-Code Programming, CNC Manufacturing and Shop Management, DIY CNC, and don’t forget the CNC Cookbook Blog–with over 4 million visitors a year it’s the most popular CNC blog by far on the web.

More Resources

G Code Commands FAQ

How many G codes are there?

There are about 100 g code commands, give or take. There are many dialects of g-code, and some have proprietary g-codes.

Milling G Code Software Windows 10

What are G Codes in CNC Machines?

This page lists all the G code commands and tells what they do and also gives a link to tutorials and examples. G codes are single letter commands that tell the CNC machine what to do. They may command motion (i.e. tell the machine where to cut) or do things like turn the spindle on or off.

G Code Milling Software

Is learning G-Code hard?

Milling G Code Software Online

Learning g-code isn’t very hard. We have a complete free online g-code tutorial to teach you as well as a g-code simulator that makes learning easy.

Why are G Codes used?

G Codes make CNC Machines programmable, which gives them the flexible to make almost any part.

What is the difference between G codes and M codes?

G-Codes are about Geometry while M-Codes are about Machine functions.

Do all CNC machines use G-code?

G-code Text Engraving Milling Software

Not all CNC machine use G-Code. Some may have both g-code and other ways of programming, for example alternate languages such as Mazak’s Mazatrol or Conversational Programming. Others, may have an alternate language and no ability to execute g-code at all.